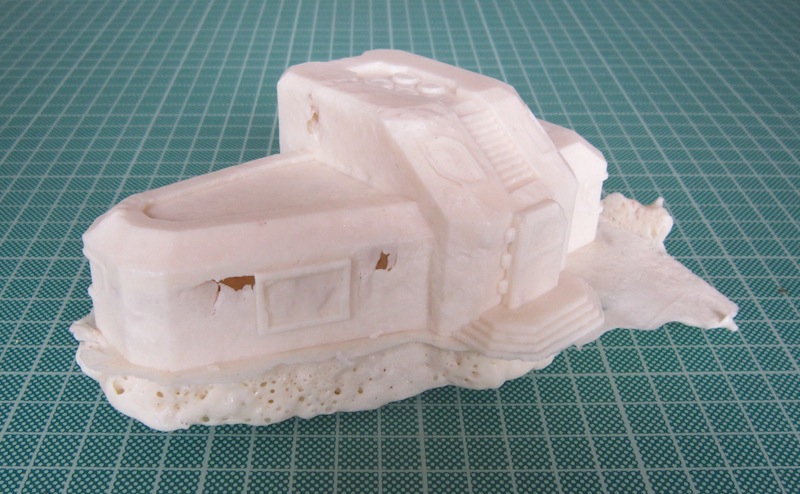

Whilst casting some 15mm building stock a few days ago something rather bizarre happened. What was supposed to be a large advanced building turned into a bit of a blob.

The resin comes in two parts (resin and hardener) which is mixed together in equal quantities. Normally everything goes according to plan but on this occasion once the resin was poured into the mould it started to expand in a style similar to fill and fix foam. It was also making a noise that would make a bowl of Rice Krispies proud. Since it was around midnight at this point I left it to calm down overnight.

We’ve been using the same type of resin for well over a decade and I’ve never had this happen before. I can only assume that the tub of resin had been contaminated in some way or was past its use by date. Certainly using the same tin of hardener with a new batch of resin has worked fine since.

The end result is far too good to simply bin. Around half of the building is now hollow and the surface has a variety of decent damage marks on it. So the plan now is to carefully cut off the lump of resin from the bottom and paint it up as a destroyed building.

So I’m off to get a new blade for my hacksaw and we’ll see how it goes.

You must be logged in to post a comment.